How to set parameter and formula for e.g. Power, Fuel, Repair and Maintenance?

Some inputs for setting parameters and formula::

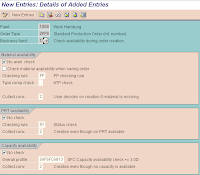

Go-to : OP7B "Parameters Overview"

Define your requirements Eg. For Power – say ZELECT like that

(Short Key work/Keyword – Electricity, Dimension " Energy", Std. Value Unit – KWH)

Then Go-to : OP19 " Standard Value Key Formula : Overview "

Select SAP1 – Normal Production and Copy as (F6) and Create new Activity Type Say eg. ZELE

Then Assign this new Parameter ZELECT and save (handle the transport request)

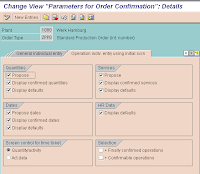

For Formula Definition :

Go-to : OP54 "Formula Definition"

Select SAP002 – Prod.: Machine Time and Copy as (F6) and Create ur new Formula Say Eg. ZELECT

And replace SAP_02 with your Parameter – ZELECT

Then it’ll look some thing like "ZELECT * SAP_09 / SAP_08 / SAP_11"

Assign The Standard Value Key " ZELE" to your Work Center-Basic Data Screen

Now Go-to Costing Tab Page assign your formula to your Predefined Activity Type for Power.

(Otherwise – First Create Secondary Cost Element (T.Code KA06), Assign this Sec. Cost Element to your new Activity Type, then KP26 " Change Activity / Price Planning"

Assign Activity Type in Work Center Costing Tab & Assign Your Formula)

You can assign max. 6 Standard Values to your WC, I.e If you want to capture Power & Fuel Consumption for an Operation you can have both parameters set as per above procedure